Established in 2009

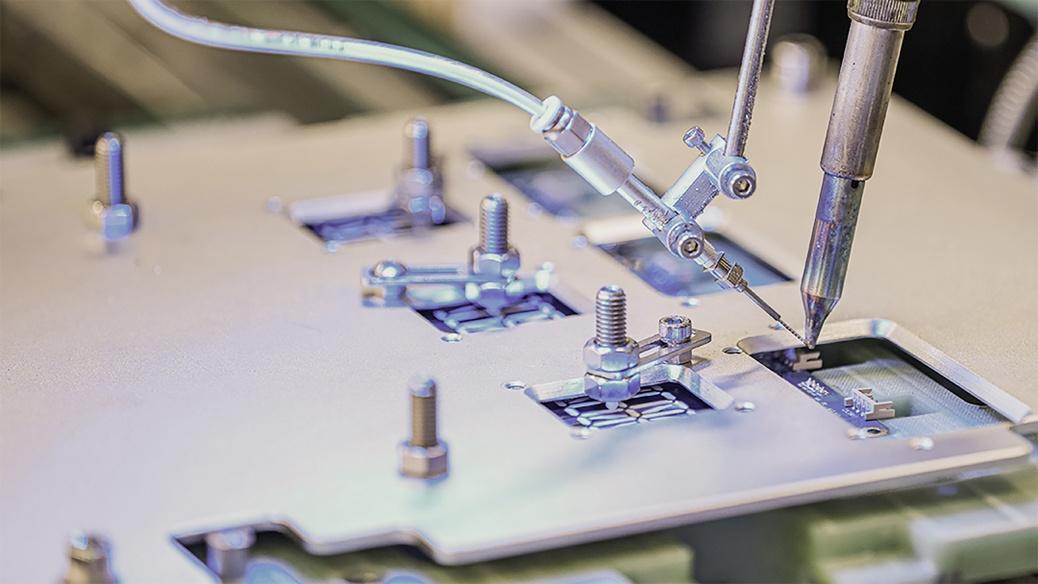

Kèo cái, it is the first national laboratory in the industry to be certified by CNAS. The test center has an independent and centralized analysis and testing laboratory of 1140 square meters. Over the past 10 years, a high-level professional technical team has been cultivated and introduced, with most of the testing engineers having more than 10 years of working experience in the escalator industry. The laboratory has purchased a batch of high-end precision scientific instruments, including: button life test equipment, motor traction machine brake performance test equipment, high and low temperature alternating wet heat test equipment, programmable constant temperature and humidity test chamber, cam loading fatigue test equipment, gate lock fatigue test equipment, EMC electromagnetic compatibility test equipment, dust test equipment, etc. Up to now, The test center has completed 48 standard developments, the test report can be mutually recognized with 71 laboratories in 57 countries and regions. With the concept of "Precision, impartiality, professionalism, and innovation", the center has realized information management of quality control, autonomous testing and laboratory safety, etc. Established standardized management systems for job responsibilities, service processes, instrument operation and training of maintenance, consumables and personnel.